A complex automobile mold can be understood as a complex mold mechanism and action, or it can be understood as a large mold, coexistence of various structures, and high design difficulty. Today, I will explain it to you, let’s take a look!

Automotive elbow products, which are structural parts, are known for their complex structures. Different from the widely used automotive interior and exterior trim parts, generally, the interior and exterior trim parts on a car are the most widely used and the largest in number, accounting for about 80% of the auto parts. Most factories make auto molds, which mainly refer to the interior and exterior of the car. Decorative mould. The automotive structural parts, including intake manifolds, elbows, water tanks, air conditioning evaporator shells, etc. are all automotive structural parts. They are known for their complex mold structure, low appearance requirements, and simple mold typing.

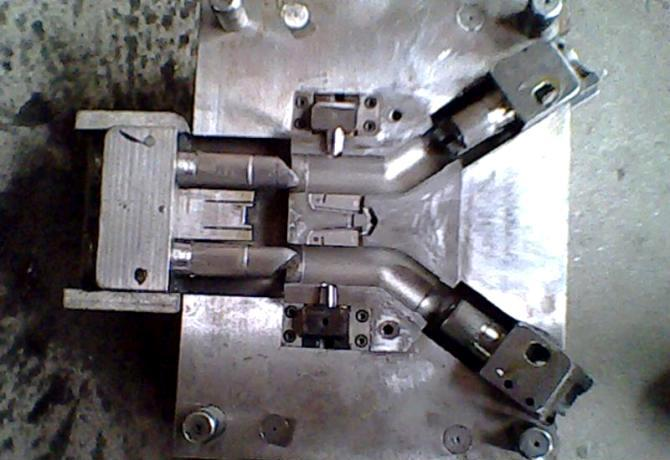

There are many mold structures, including elbow core pulling and cylinder motor drive, which can be called a large collection of automobile mold structures.

1. Put the safety and convenience of production (processing/assembly/injection) first. “Customer is God” is not only the purpose of the service industry, but also our purpose. For injection molding production, the first thing is to match, and the second is to be convenient.

2. Follow customer standard requirements.

If the customer does not require it, follow the company’s internal standards.

Highlights of Client Standards:

1). Mold steel and accessories material, hardness requirements

2). The interface between the mold and the injection molding machine. (Water\electric\oil interface\code mold\KO hole\positioning ring\nozzle size)

3). Mold lifting requirements (hoisting balance, etc.)

4). The brand of mold standard parts. (Note whether original or imitation is required)

5). Basic practices of the structure of each part of the mold, such as water transport requirements, slider/sloping top form, gate form, etc.

6). Sometimes you need to pay attention to the thread requirements. (Tightening thread and pipe thread)

7). In rare cases, the drawings provided by customers are different from our commonly used 3rd viewing angle

For each set of molds, it is also necessary to pay attention to product requirements and pick-up methods.

Post time: Jan-13-2022